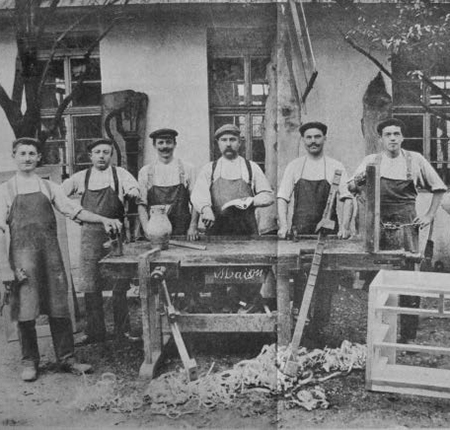

Over 95 Years of Manufacturing Excellence

Thank you for reading Brown Wood Inc.’s Ad in FDMC‘s September 2023 Issue! At Brown Wood Inc., we aim to be your single source American-Made custom wood components partner. Through our two distinctive brands, Made-To-Spec® and Designs of Distinction®, Brown Wood Inc. serves as an industry leading partner to manufacturers, retailers, distributors, engineers, architects and interior designers.

Through Designs of Distinction and Made-to-Spec, Brown Wood Inc. can help you produce virtually any item at any quantity. We like to say, “there’s nothing we can’t craft.”

ALL CUSTOM WOOD PRODUCTS

Rooted in America for over 90 years, Made-to-Spec by Brown Wood, Inc. offers a versatile range of custom wood parts & components. From handles to retail displays, custom solutions catering to every niche and need is our specialty while quality and character is our promise to you.

Founded in 1927 and FSC certified since 2001, Brown Wood offers cutting edge capabilities, a consultative approach, and a vast array of products to help each customers project realize it’s greatest potential.

MARKETS & CAPABILITIES

Need a unique wood part, component, or finished product? Whether you manufacture cabinetry, toys or tools, we have the production capabilities to help you go to market. We specialize in manufacturing custom wood parts and components to your exact specifications. If you are looking for durable unique wooden parts, Made-to-Spec is the custom wood parts manufacturer to meet your needs.

Our turnings capabilities are unmatched in the market: Diameters up to 24 inches and lengths up to 19 feet.

Markets we serve include Kitchen & Bath, Store Fixtures, Product Displays, Gifts & Premiums, Furniture, Hospitality, and Ad Specialty/Promotional Items.

MATERIALS, FINISHES, & MORE

We work with a variety of materials including hardwoods, softwoods, veneers, laminates, composites, and more. Bamboo, Beech, Chestnut, Maple, Mahogany, Sycamore, Walnut, Reclaimed Wood… you name it, we can work with it. Finish options range from water-based or oil-based stains and paints to powder coating and polyurethane. Secondary operations – edge banding, precision drilling, tapers, tenons, roping, reeding, or fluting – can all be taken care of in-house before your custom component ships. We can take care of the “extras,” too! Assembly, packaging, drop-shipment, imprinting, warehousing, and more.

RESPONSIVE. KNOWLEDGEABLE. CAPABLE. FLEXIBLE.

Many wood providers only supply parts, without considering the big picture plan or time-frame. The result: you expend valuable time and resources just managing bids and logistics. Brown Wood is different. We work collaboratively with you, bringing our expertise and capabilities to add value to your projects. Flexibility defines our business.

What makes us the best option for your custom wood components?

- Ability to produce virtually anything custom

- Value engineering for cost savings

- Tools for make-or-buy analysis

- Immediate, clear, concise pricing (no cost overruns)

- Ability to use FSC certified materials as required

- Production, finishing, assembly, and packaging

- Long and short runs

- Vast production capabilities in the USA

Your next custom wood component starts here. Request a quote today!